Product&Service

Over the past 20 years, we have been committed to the R&D, manufacturing and installation of various environmental protection equipment. This equipment has been applied in diverse settings such as chemical plants, power plants, oil refineries and metal smelters, and has received high acclaim.

About Our Equipment

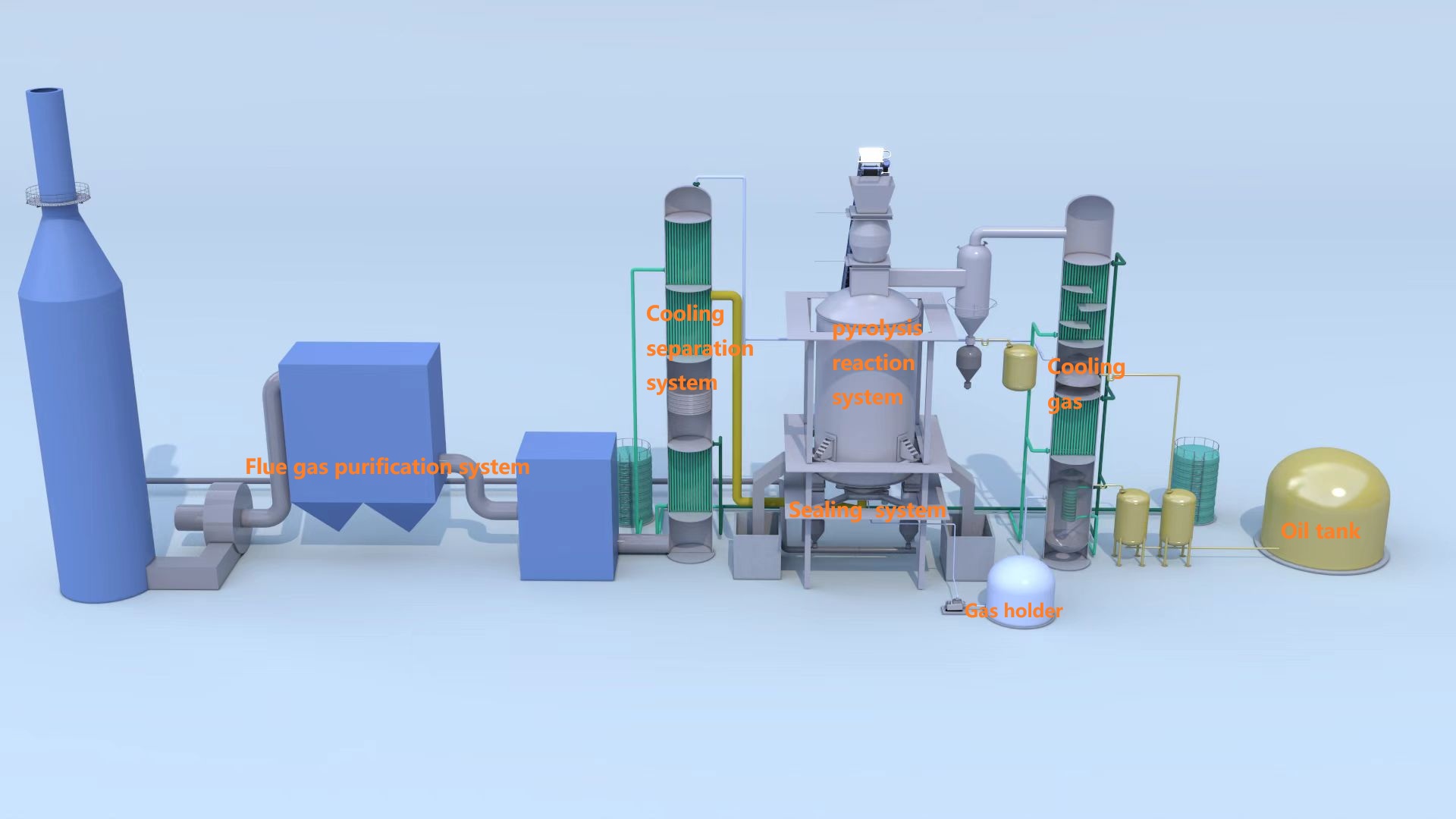

Vertical Continuous Self Heating Pyrolysis Equipment is our latest R&D product. It can efficiently pyrolyze high-molecular polymers such as tires, plastics, and organic waste to obtain energy and other products.

The pyrolysis equipment is a vertical equipment, with the lower part being the separation zone, the middle and upper sections being the pyrolysis zone, and the top being the feeding zone, which enables continuous operation.

When the equipment is in operation, raw materials are continuously fed into the pyrolysis reaction equipment and heated to decompose into carbon black, pyrolysis oil, combustible gas and steel wires in an oxygen-deficient or oxygen-free environment.

Our equipment is different from traditional horizontal pyrolysis equipment. Ours is extremely advanced and special, as it is vertical. Compared with traditional horizontal equipment, it covers a smaller area (about 300 square meters), is more energy-efficient (approximately half the power consumption of traditional equipment), can continuously feed tires for pyrolysis, and allows whole tires to be put in – which means it does not require front-end tire crushing equipment. It can operate outdoors, so you don't need to build a workshop for it. For a detailed comparison, please refer to the table below:

| Comparison of Horizontal and Vertical Equipment | ||

| type | Mirshine vertical continuous cracking technology. | Horizontal cracking technology on the market. |

| Process route | It can achieve continuous operation under the premise of safety and environmental protection. | Intermittent operation requires stopping for cleaning after driving for a period of time, which poses safety and environmental risks. |

| Floor space | The vertical rotary cracking furnace is integrated and occupies a small area. | The cracking unit occupies a large area. |

| power consumption | Utilizing potential energy difference, the overall power consumption is 50-60kwh/te | There is a tire crushing process, which consumes 120kwh/t of electricity and 80kwh/t of electricity for cracking. |

| Feeding system | 1. Double feeding quick opening valve, hydraulically driven, quick opening and closing, reducing the entry of air. At the same time, a buffer tank is set between the two valves to use the heat of the flue gas to heat the raw materials, drive away excess air, form a slight negative pressure, and ensure anaerobic or anoxic cracking. 2. Can directly process whole or large tires without crushing | For single-port feeding, the material must be crushed first and then fed. The feeding speed is slow and there is a risk of air leakage. |

| heat transfer system | It adopts internal heat transfer method, the outer tube is insulated with heat-resistant bricks, and at the same time, M-shaped heat transfer tubes and spiral heat sinks are added to the inner heat conduction tube to increase the heat transfer area, slow down the loss of hot flue gas, and enhance the heat transfer effect. | External heat transfer is adopted, and the rotating inner wall of the cracking furnace is lined with temperature-resistant bricks. |

| Rotary mechanism | The rotary mechanism is set at the bottom and uses high-temperature resistant graphite packing to ensure no leakage. | The slewing mechanism is on the side and sealed with graphite packing. |

| Oil outlet system | It can distinguish between light oil and heavy oil. | Generally no distinction is made. |

| Environmental protection system | Standard emission of flue gas system can be achieved. | It is relatively simple, and the exhaust gas may cause pollution and odor in the surrounding environment. |

| Intelligent control system | It can realize full automation, precise control, interlocking alarm and complete safety facilities. | Semi-automatic, loading and unloading need to be done manually. |

| Remote Services | Able to realize remote guidance service | The degree of automation is not necessarily |

| Service life | The high-temperature part uses stainless steel and is molded as a whole as much as possible to reduce maintenance and increase service life. | Made of Q355R material, its service life is slightly shorter. |

About manufacturing and installation

We have experienced engineers and technicians, advanced production workshops, as well as a sound quality and safety management system.

We have 15 independent professional construction teams that are highly efficient and specialized. Each team is equipped with professional installation engineers and skilled technical workers

.

About Warranty and Maintenance

We provide full-project lifecycle services including design solutions, processing and manufacturing, installation and commissioning, as well as after-sales operation and maintenance after equipment put into operation.。

Our equipment comes with a warranty period of at least one year. Our equipment can adopt accessories that meet CE or other certifications according to your needs. This ensures that after the warranty period expires, you can still purchase all spare parts in your country, facilitating maintenance.